It’s a beautiful thing to witness the human mind at full throttle when creativity flows unhinged in response to the pressure to innovate. The resulting orchestra is what’s led Ford to get around strict fuel economy regulations by modernizing the internal combustion engine and building EcoBoost technology into a brand of its own. The sad thing is, it’s still not enough. Regulators keep choking engines—literally and figuratively— and it won’t be long until CAFE standards require automakers to achieve a 54.5 mpg fleet average.

Ford Engineer Patents Exotic Engines With One Turbocharger Per Cylinder

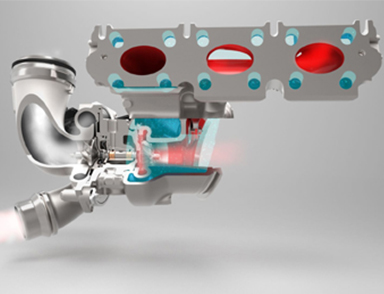

Even for Ford’s EcoBoost technology, that’s pushing it, but Car and Driver claims that longtime Blue Oval engine designer Jim Clarke has a million dollar idea that could save the internal combustion engine (or at least prolong its life) by extracting even more horsepower out of a smaller engine block. Rather than using staged turbos or an AMG-style Hot V engine, Clarke’s concept gets a small boosted engine to make instantaneous horsepower off the line by speeding up the intake and and exhaust processes to get air into the cylinder more quickly and then out to the turbocharger as soon as combustion byproducts become available. It's even cooler than Ford's idea for a water-injection system!

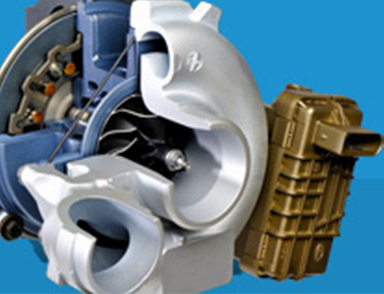

That's because the concept alters a turbocharged engine in two ways: by using two individual throttle bodies per cylinder (one per intake port) placed right next to the cylinder head to get air into the cylinders more quickly and by placing individual turbochargers as close as possible to the exhaust port of each cylinder. Yes, you heard right. That means each cylinder gets a turbocharger all to itself. It might sound like a recipe for sickening amounts of horsepower, but in this case it’s used to get boosted air into the engine more quickly. In order to fit all that under one hood, the turbochargers must be about 20% smaller in size than a conventional spool. A smaller turbo also has less rotating inertia, further speeding up the boosting process.